Melt Pump

- Gear melt pump for high viscosity me

- Plastic melt pump for extruder

- Extruding pump for polymer

- Pressurized melt pump for extruder

- High temperature and high pressure m

- Gear pump for rubber extruder

- Polymer melt pump for reaction kettl

- Melt pump for reaction kettle

- Spinning gear metering pump

- Chemical transporting and dosing pum

Feeding System

- Liquid loss in weight feeder

- Volume feeding machine

- Multi-component loss in weight feede

- Micro loss in weight metering feeder

- Single screw gravimetric dosing feed

- Twin screw loss in weight metering f

Screen Changer

- Manual control screen changer

- Double plate hydraulic screen change

- Automatic mesh belt continuous scree

- Double piston four screen cavities s

- Single plate double screen cavities

- Single piston double screen cavities

- Double piston four screen cavities b

- Double piston double screen cavities

contact us

- Batte Machinery Zhengzhou Co., Ltd.

- E-mail: info@battemachinery.com

- Skype: Battemachinery

- Tel: +86 371 67991755

- After-sales Tel: +86 371 67997677 / 67997877

- Mob: +86 15838331071

- Address: No.11 Changchun Road, High & New Technology Development Zone, Zhengzhou, China.

News

- Melt Pump Installation Schemes

- Loss in weight feeder application

- Structure of Batte spinning pumps

- Advantages of Batte gear spinning pu

- Effect of structural features of the

- Effect of material properties for in

- BATTE May is thriving!

- K 2016-The world’s No.1 Trade Fair

- Latest information about CHINAPLAS 2

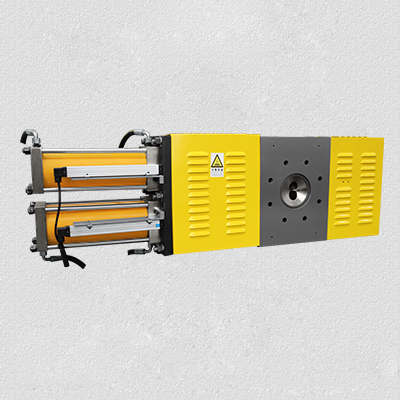

Double plate hydraulic screen changer

Double plate hydraulic screen changer

Double plate hydraulic screen changer.pdf

Double plate hydraulic screen changer.pdf

Introduction of Double plate screen changer:

◆ As dual-channel double screen cavities screen changer, this series screen changer can provide uninterrupted operation.

◆ With exhaust structure, filtration process will not stop when replace filters.

◆ It is suitable for most of polymer extruded production.

◆ Filtration process will not stop when replace filters, it make the pressure stable.

◆ It can work well in 25-30Mpa pressure candition.

◆ It is mainly used for chemical, blown film, flat film, cast film, pipe, plate, wire, fiber, cutting line, recycling and so on.

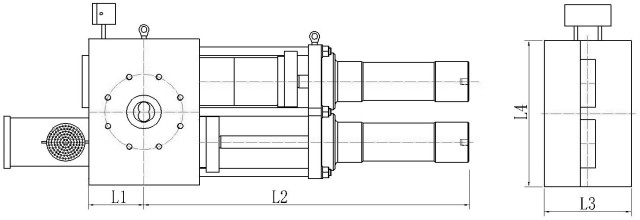

Structure of Hydraulic screen changer:

Parameters of Double screen cavities screen changer:

Type

Capacity (kg/h)

Dimension (mm)

Screen size

Heater

L1

L2

L3

L4

Diameter (mm)

Area (cm2)

Quantity

Voltage (v)

Power (w)

ZB-DSP-80

110-300

140

775

220

330

80

50*2

6

230/400

1200/1700

ZB-DSP-100

180-500

170

895

250

400

100

78*2

6

230/400

1600/2000

ZB-DSP-120

350-800

200

1005

310

470

120

113*2

6

230/400

200/2400

ZB-DSP-150

450-1200

245

1170

350

560

150

176*2

6

230/400

2400/3000

ZB-DSP-180

500-1500

290

1335

440

600

180

254*2

6

230/400

4000/4800

ZB-DSP-200

800-2500

320

1455

450

670

200

314*2

8

230/400

4500/5300

ZB-DSP-250

1400-3700

395

1760

490

760

250

490*2

8

230/400

5000/6000

Notes: The capacity will be affected by the fluidity, filter fineness and purity of materials.

Double plate hydraulic screen changer.pdf

Double plate hydraulic screen changer.pdf

Previous:Automatic mesh belt continuous screen changer

Next:Manual control screen changer