Melt Pump

- Gear melt pump for high viscosity me

- Plastic melt pump for extruder

- Extruding pump for polymer

- Pressurized melt pump for extruder

- High temperature and high pressure m

- Gear pump for rubber extruder

- Polymer melt pump for reaction kettl

- Melt pump for reaction kettle

- Spinning gear metering pump

- Chemical transporting and dosing pum

Feeding System

- Liquid loss in weight feeder

- Volume feeding machine

- Multi-component loss in weight feede

- Micro loss in weight metering feeder

- Single screw gravimetric dosing feed

- Twin screw loss in weight metering f

Screen Changer

- Manual control screen changer

- Double plate hydraulic screen change

- Automatic mesh belt continuous scree

- Double piston four screen cavities s

- Single plate double screen cavities

- Single piston double screen cavities

- Double piston four screen cavities b

- Double piston double screen cavities

contact us

- Batte Machinery Zhengzhou Co., Ltd.

- E-mail: info@battemachinery.com

- Skype: Battemachinery

- Tel: +86 371 67991755

- After-sales Tel: +86 371 67997677 / 67997877

- Mob: +86 15838331071

- Address: No.11 Changchun Road, High & New Technology Development Zone, Zhengzhou, China.

News

- Melt Pump Installation Schemes

- Loss in weight feeder application

- Structure of Batte spinning pumps

- Advantages of Batte gear spinning pu

- Effect of structural features of the

- Effect of material properties for in

- BATTE May is thriving!

- K 2016-The world’s No.1 Trade Fair

- Latest information about CHINAPLAS 2

Loss in weight feeder application

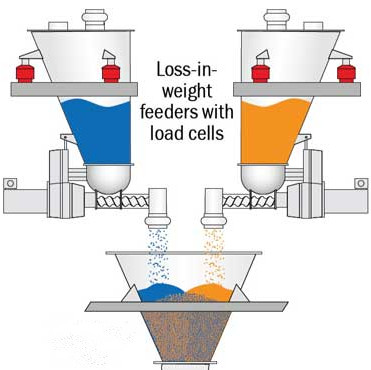

Application of Loss-in-weight-feeder

Batte specializes in designing and integrating both liquid and powder loss-in-weight systems for applications such as extrusion, pharmaceutical industry, chemical industry, food.

Loss-in-Weight gravimetric feeders is suitable for materials with varying bulk density and for material handling automation. It is the best choice for long term accuracy, repeatability and quality documentation, and where dust control is a concern.

Single screw Loss-in-Weight feeders (single screw feeder, single screw metering feeder) are used for pellets and free-flowing powders.

Twin screw loss-in-weight feeders (twin screw feeder, twin screw metering feeder) are most effective for pigments, sticky, bridging or flooding powders, fiberglass.

Microfeeder(single screw microfeeder, twin screw micro feeder) is suitable for Gravimetric feeding of free flowing to difficult powders (e.g. lumpy or bridge building materials) and micropellets. The weigh bridge is a sanitary version and is therefore suitable for quick and easy cleaning.

Liquid feeder ( Liquid Loss-in-Weight Feeder )is available in special skid mounted designs which are completely portable for movement throughout the plant.

Previous:Structure of Batte spinning pumps

Next:Melt Pump Installation Schemes