Melt Pump

- Gear melt pump for high viscosity me

- Plastic melt pump for extruder

- Extruding pump for polymer

- Pressurized melt pump for extruder

- High temperature and high pressure m

- Gear pump for rubber extruder

- Polymer melt pump for reaction kettl

- Melt pump for reaction kettle

- Spinning gear metering pump

- Chemical transporting and dosing pum

Feeding System

- Liquid loss in weight feeder

- Volume feeding machine

- Multi-component loss in weight feede

- Micro loss in weight metering feeder

- Single screw gravimetric dosing feed

- Twin screw loss in weight metering f

Screen Changer

- Manual control screen changer

- Double plate hydraulic screen change

- Automatic mesh belt continuous scree

- Double piston four screen cavities s

- Single plate double screen cavities

- Single piston double screen cavities

- Double piston four screen cavities b

- Double piston double screen cavities

contact us

- Batte Machinery Zhengzhou Co., Ltd.

- E-mail: info@battemachinery.com

- Skype: Battemachinery

- Tel: +86 371 67991755

- After-sales Tel: +86 371 67997677 / 67997877

- Mob: +86 15838331071

- Address: No.11 Changchun Road, High & New Technology Development Zone, Zhengzhou, China.

News

- Melt Pump Installation Schemes

- Loss in weight feeder application

- Structure of Batte spinning pumps

- Advantages of Batte gear spinning pu

- Effect of structural features of the

- Effect of material properties for in

- BATTE May is thriving!

- K 2016-The world’s No.1 Trade Fair

- Latest information about CHINAPLAS 2

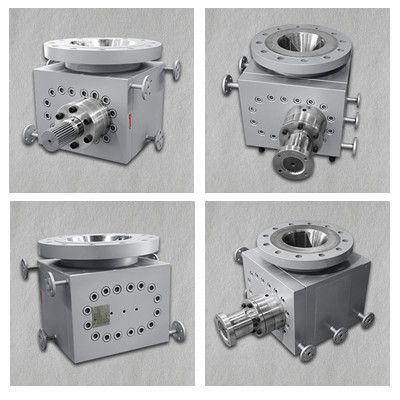

Melt pump for reaction kettle

Melt pump for reaction kettle

ZB-F Melt pump for reaction kettle.pdf

ZB-F Melt pump for reaction kettle.pdf

Introduction of Melt pump for reaction kettle

Melt pump for reaction kettle is mainly used for transporting medium or high viscosity medium out of the vacuum reaction kettle. On basis of large suction inlet flange design, the high viscosity medium is able to absorb inside under vacuum conditions. This series of reaction kettle pump is primarily applicable for ABS, PS, PET, PC, SAN, PP, PE Bioploymers etc.

Technical Parameter of Reaction kettle pump

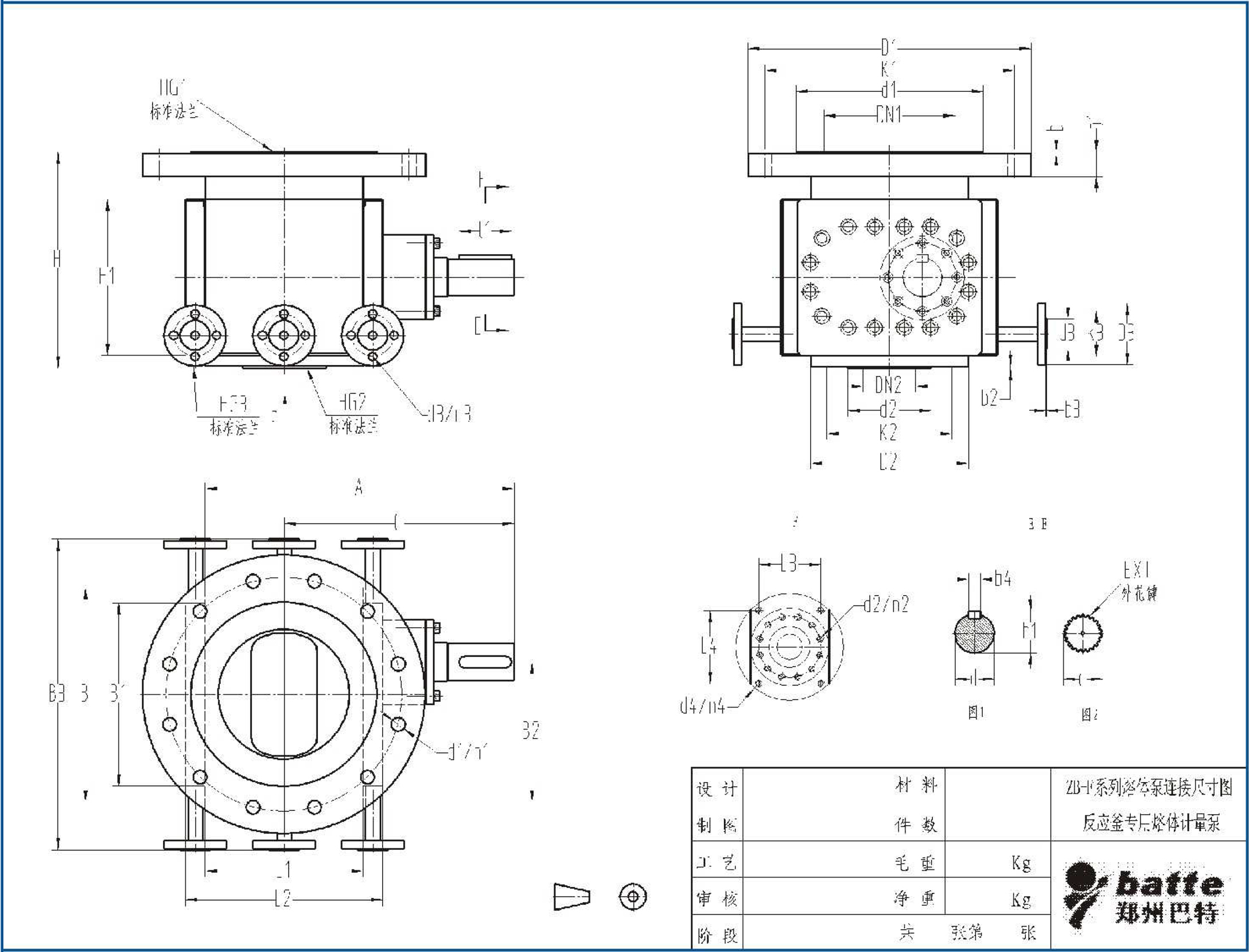

◆ Melt Pump Body: stainless steel, carbon steel, hastelloy, monel

◆ Gear: tool steel, nitrided steel, special material and wear-resistant coating

◆ Tooth profile: Straight tooth, Helical tooth, Herringbone tooth

◆ Sliding Bearing: tool steel, Ti-Ta alloy, silver-nickel, special material and wear-resistant coating

◆ Shaft Sealing: mechanical seal, Screw sealing+Packing seal, flushing fluid combined sealing

◆ Heating System: Conduction oil heating, Biphenyl gas

Operating Parameter of Melt pump for reaction kettle

◆ Theory: Positive Displacement Gear Pump

◆ Structure: Gear Pump

◆ Usage: Plastic, Rubber Pump and Fiber

◆ Power: Electric or Oil

◆ Fuel: No Need

◆ Pressure: High Pressure

◆ Volume Range: 0.5CC - 12000CC

◆ Viscosity: ≤40000 Pas

◆ Working Temperature: ≤400°C(750°F)

◆Cleaning Temperature: ≤450°C(850°F)

◆ Inlet Pressure: Vacuum--1.5MPa

◆ Outlet Pressure: 40Mpa

Features of Reaction kettle pump

◆ Stabilizing outlet pressure;

◆ Improving the products quality;

◆ Increasing the extrusion output;

◆ Reducing unit energy consumption;

◆ Prolonging the service time of extruder.

Structure of Reaction kettle gear pump

Parameters of Reaction kettle pump

| Type | CC/Rev | Capacity (L/H) | Heating power (kw) | Dirven system (kw) | Pressure | Temperature |

| ZB-0.2 | 0.2 | 0.2-0.6 | 0.5 | 0.37 | Inlet pressure: ≥0Mpa Exit pressure: ≤35Mpa | Operating temperature:≤350℃ Clearing temperature:≤450℃ |

| ZB-1 | 1 | 1-3 | 1 | 0.5 | ||

| ZB-2 | 2 | 2-6 | 1 | 0.75 | ||

| ZB-5 | 5 | 5-15 | 1 | 1.1 | ||

| ZB-10 | 10 | 10-30 | 1 | 1.5 | ||

| ZB-20 | 20 | 20-60 | 2 | 2.2 | ||

| ZB-31.5 | 31.5 | 30-90 | 2 | 3 | ||

| ZB-50 | 50 | 50-150 | 2 | 4 | ||

| ZB-100 | 100 | 100-300 | 3 | 5.5 | ||

| ZB-150 | 150 | 150-450 | 4 | 7.5 | ||

| ZB-200 | 200 | 200-600 | 4 | 11 | ||

| ZB-250 | 250 | 250-750 | 5 | 15 | ||

| ZB-315 | 315 | 300-900 | 6 | 18.5 | ||

| ZB-400 | 400 | 400-1200 | 8 | 22 | ||

| ZB-500 | 500 | 500-1500 | 10 | 30 | ||

| ZB-630 | 630 | 600-1800 | 12 | 37 | ||

| ZB-800 | 800 | 800-2400 | 15 | 45 | ||

| ZB-1000 | 1000 | 1000-3000 | 18 | 55 | ||

| ZB-1500 | 1500 | 1200-4500 | 20 | 75 |

ZB-F Melt pump for reaction kettle.pdf

ZB-F Melt pump for reaction kettle.pdf

Next:Extruding pump for polymer