Melt Pump

- Gear melt pump for high viscosity me

- Plastic melt pump for extruder

- Extruding pump for polymer

- Pressurized melt pump for extruder

- High temperature and high pressure m

- Gear pump for rubber extruder

- Polymer melt pump for reaction kettl

- Melt pump for reaction kettle

- Spinning gear metering pump

- Chemical transporting and dosing pum

Feeding System

- Liquid loss in weight feeder

- Volume feeding machine

- Multi-component loss in weight feede

- Micro loss in weight metering feeder

- Single screw gravimetric dosing feed

- Twin screw loss in weight metering f

Screen Changer

- Manual control screen changer

- Double plate hydraulic screen change

- Automatic mesh belt continuous scree

- Double piston four screen cavities s

- Single plate double screen cavities

- Single piston double screen cavities

- Double piston four screen cavities b

- Double piston double screen cavities

contact us

- Batte Machinery Zhengzhou Co., Ltd.

- E-mail: info@battemachinery.com

- Skype: Battemachinery

- Tel: +86 371 67991755

- After-sales Tel: +86 371 67997677 / 67997877

- Mob: +86 15838331071

- Address: No.11 Changchun Road, High & New Technology Development Zone, Zhengzhou, China.

News

- Melt Pump Installation Schemes

- Loss in weight feeder application

- Structure of Batte spinning pumps

- Advantages of Batte gear spinning pu

- Effect of structural features of the

- Effect of material properties for in

- BATTE May is thriving!

- K 2016-The world’s No.1 Trade Fair

- Latest information about CHINAPLAS 2

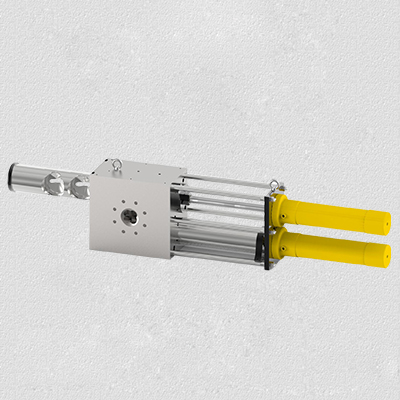

Double piston four screen cavities screen changer

Double piston four screen cavities screen changer

Double piston four screen cavities screen changer.pdf

Double piston four screen cavities screen changer.pdf

Introduction of four screen cavities screen changer:

◆ As four-channel four screen cavities screen changer, four screen cavities can work simultaneously which can provide uninterrupted operation.

◆ Exhaust structure can fully exhaust the gas in material and the other screen cavities, which can prevent gas coming into being during production, improve the product quality.

◆ Four-channel double screen cavities increase the filter area, which can improve the output and quality.

◆ Larger filter area is suitable for various different material and extrusion.

◆ Well sealed, rigid sealing, long service life.

◆ This series screen changer is suitable for high productivity, high efficiency, high quantity and continuous production of large extrusion plant.

◆ Reasonable structure, easy to operate, high quality.

◆ Customization, according to the customer special request to design and process

◆ Safety hood is equipped.

◆ It’s suitable for chemical fiber, blown film, flat film, cast film, pipe, plate, wire, fiber, granulating, recycling, pelletizing, etc.

Structure of Double piston screen changer:

Parameters of Hydraulic screen changer:

| Type | Capacity (kg/h) | Dimension (mm) | Screen size | Heater | |||||

| L1 | L2 | L3 | Diameter (mm) | Area (cm2) | Quantity | Voltage (v) | Power (w) | ||

| ZB-DP-4R-120 | 260-760 | 180 | 1160 | 220 | 100 | 78*4 | 6 | 230/400 | 1000/1300 |

| ZB-DP-4R-145 | 580-1400 | 225 | 1420 | 270 | 125 | 123*4 | 6 | 230/400 | 2000/2400 |

| ZB-DP-4R-170 | 750-2000 | 260 | 1595 | 310 | 150 | 177*4 | 6 | 230/400 | 3000/3500 |

| ZB-DP-4R-195 | 1350-3000 | 315 | 1890 | 380 | 175 | 240*4 | 6 | 230/400 | 3500/4000 |

| ZB-DP-4R-220 | 1650-3800 | 350 | 2100 | 410 | 200 | 314*4 | 10 | 230/400 | 3500/4000 |

| ZB-DP-4R-250 | 2100-5200 | 405 | 2395 | 460 | 230 | 415*4 | 12 | 230/400 | 3500/4000 |

| ZB-DP-4R-280 | 4500-8500 | 450 | 2760 | 500 | 250 | 490*4 | 12 | 230/400 | 4200/5000 |

Notes: The capacity will be affected by the fluidity, filter fineness and purity of materials.

Double piston four screen cavities screen changer.pdf

Double piston four screen cavities screen changer.pdf

Next:Automatic mesh belt continuous screen changer