Melt Pump

- Gear melt pump for high viscosity me

- Plastic melt pump for extruder

- Extruding pump for polymer

- Pressurized melt pump for extruder

- High temperature and high pressure m

- Gear pump for rubber extruder

- Polymer melt pump for reaction kettl

- Melt pump for reaction kettle

- Spinning gear metering pump

- Chemical transporting and dosing pum

Feeding System

- Liquid loss in weight feeder

- Volume feeding machine

- Multi-component loss in weight feede

- Micro loss in weight metering feeder

- Single screw gravimetric dosing feed

- Twin screw loss in weight metering f

Screen Changer

- Manual control screen changer

- Double plate hydraulic screen change

- Automatic mesh belt continuous scree

- Double piston four screen cavities s

- Single plate double screen cavities

- Single piston double screen cavities

- Double piston four screen cavities b

- Double piston double screen cavities

contact us

- Batte Machinery Zhengzhou Co., Ltd.

- E-mail: info@battemachinery.com

- Skype: Battemachinery

- Tel: +86 371 67991755

- After-sales Tel: +86 371 67997677 / 67997877

- Mob: +86 15838331071

- Address: No.11 Changchun Road, High & New Technology Development Zone, Zhengzhou, China.

News

- Melt Pump Installation Schemes

- Loss in weight feeder application

- Structure of Batte spinning pumps

- Advantages of Batte gear spinning pu

- Effect of structural features of the

- Effect of material properties for in

- BATTE May is thriving!

- K 2016-The world’s No.1 Trade Fair

- Latest information about CHINAPLAS 2

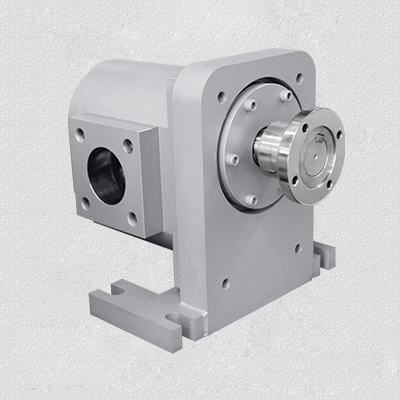

Chemical transporting and dosing pump

Chemical transporting and dosing pump

ZB-X Chemical transporting and dosing pump.pdf

ZB-X Chemical transporting and dosing pump.pdf

Introduction of Chemical pump

Batte chemical transporting and metering pump mainly used for conveying and metering of fluids with low medium viscosity. The application range goes from classic transfer and metering tasks in the chemical and pharmaceutical industries up to the conveyance of monomers, oligomers and prepolymers during the production of polymers. Decades of experience in construction and an optimum selection of materials, make this type of chemical pump suitable for even the most demanding tasks and are outstanding in their reliability and metering precision in both vacuum and high pressure applications.

Features of Chemical gear pump

◆ Can meet the demand of chemical craft .

◆ High temperature , low temperature resistant .

◆ Corrosion resistant .

◆ Resistant to wear and tear

◆ No leakage .

◆ Can transport liquid of critical state .

Application of Chemical dosing pump

Batte chemical Pumps are widely applied in waste water treatment, chemical industry, petrochemical industry, painting, ceramics, environmental protection, printing and dyeing, etc. to deal with all kinds of corrosive, volatile, flammable, poisonous fluids with particles and high viscosity. Batte chemical pumps are adaptable for most highly aggressive or corrosive media.

| Organic and inorganic chemicals | Alcohols, additives, bases, esters, glycerine, resins, hardeners, isocyanates, monomers, oils, phenol, acids, biodiesel, asphalt, bitumen, tar, hot melt, glues, waxes, etc. |

| Polymers | Cellulose acetate, Nylon 66, prepolymers, etc. |

| Food industry | Vegetable oils, butter, margarine, flavourings, chocolate, fudge, liquorice, chewing gum, vitamins, syrup, gelatine, etc. |

| Pharmaceutical and Cosmetic Products | Amino acids, lotions, shampoo, vitamins, etc. |

| Housing | Non-alloyed and alloyed steels, tantalum, titanium, Hastelloy, ceramic |

Parameters of chemical transporting pump

Max. Outlet Pressure: 700Bar

Max. Outlet Pressure: 200Bar

Max. Differential Pressure: 500Bar

Viscosity:20000Pa.s

Temperature: 510 Celsius degree

Structure of chemical metering pump: According to your requirements or drawing.

ZB-X Chemical transporting and dosing pump.pdf

ZB-X Chemical transporting and dosing pump.pdf

Next: I'm sorry no