Melt Pump

- Gear melt pump for high viscosity me

- Plastic melt pump for extruder

- Extruding pump for polymer

- Pressurized melt pump for extruder

- High temperature and high pressure m

- Gear pump for rubber extruder

- Polymer melt pump for reaction kettl

- Melt pump for reaction kettle

- Spinning gear metering pump

- Chemical transporting and dosing pum

Feeding System

- Liquid loss in weight feeder

- Volume feeding machine

- Multi-component loss in weight feede

- Micro loss in weight metering feeder

- Single screw gravimetric dosing feed

- Twin screw loss in weight metering f

Screen Changer

- Manual control screen changer

- Double plate hydraulic screen change

- Automatic mesh belt continuous scree

- Double piston four screen cavities s

- Single plate double screen cavities

- Single piston double screen cavities

- Double piston four screen cavities b

- Double piston double screen cavities

contact us

- Batte Machinery Zhengzhou Co., Ltd.

- E-mail: info@battemachinery.com

- Skype: Battemachinery

- Tel: +86 371 67991755

- After-sales Tel: +86 371 67997677 / 67997877

- Mob: +86 15838331071

- Address: No.11 Changchun Road, High & New Technology Development Zone, Zhengzhou, China.

News

- Melt Pump Installation Schemes

- Loss in weight feeder application

- Structure of Batte spinning pumps

- Advantages of Batte gear spinning pu

- Effect of structural features of the

- Effect of material properties for in

- BATTE May is thriving!

- K 2016-The world’s No.1 Trade Fair

- Latest information about CHINAPLAS 2

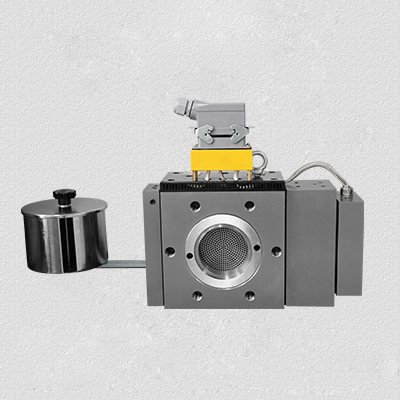

Automatic mesh belt continuous screen changer

Automatic mesh belt continuous screen changer

Automatic mesh belt continuous screen changer.pdf

Automatic mesh belt continuous screen changer.pdf

Introduction of Automatic mesh belt continuous screen changer:

◆ This series screen changer is consisted of screen changer body, heating/cooling system, electric control system, etc.

◆ The control system can control filtration time and speed automatically.

◆ This series screen changer is fully automatic and continuous.

◆ Excellent output stability, product has no deformation, quality stability.

◆ There is no waster or scrap during whole production, low material consumption.

◆ The filter length can be customized range from 10mm to 20mm, and can be used continuously for 2-6 months.

◆ It’s suitable for plastic polymer, such as PP, PE, ABS, PS, etc.

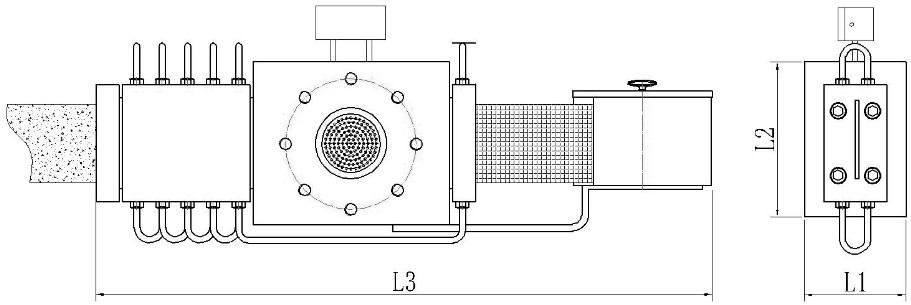

Structure of Automatic screen changer:

Parameters of Mesh belt continuous screen changer:

| Type | Capacity (kg/h) | Dimension (mm) | Screen size | Heater | ||||

| L1 | L2 | L3 | Diameter (mm) | Area (cm2) | Voltage (v) | Power (w) | ||

| ZB-ACB-50 | 30-85 | 150 | 165 | 540 | 50 | 20 | 230/400 | 5200 |

| ZB-ACB-70 | 75-200 | 160 | 170 | 560 | 70 | 38 | 230/400 | 5400 |

| ZB-ACB-90 | 100-290 | 170 | 185 | 580 | 90 | 64 | 230/400 | 5800 |

| ZB-ACB-100 | 130-350 | 180 | 215 | 605 | 100 | 78 | 230/400 | 6200 |

| ZB-ACB-120 | 190-500 | 185 | 230 | 645 | 120 | 113 | 230/400 | 6500 |

| ZB-ACB-150 | 350-800 | 200 | 265 | 700 | 150 | 176 | 230/400 | 7200 |

| ZB-ACB-180 | 450-1200 | 220 | 305 | 760 | 180 | 254 | 230/400 | 8200 |

Notes: The capacity will be affected by the fluidity, filter fineness and purity of materials.

Automatic mesh belt continuous screen changer.pdf

Automatic mesh belt continuous screen changer.pdf

Next:Double plate hydraulic screen changer