Melt Pump

- Gear melt pump for high viscosity me

- Plastic melt pump for extruder

- Extruding pump for polymer

- Pressurized melt pump for extruder

- High temperature and high pressure m

- Gear pump for rubber extruder

- Polymer melt pump for reaction kettl

- Melt pump for reaction kettle

- Spinning gear metering pump

- Chemical transporting and dosing pum

Feeding System

- Liquid loss in weight feeder

- Volume feeding machine

- Multi-component loss in weight feede

- Micro loss in weight metering feeder

- Single screw gravimetric dosing feed

- Twin screw loss in weight metering f

Screen Changer

- Manual control screen changer

- Double plate hydraulic screen change

- Automatic mesh belt continuous scree

- Double piston four screen cavities s

- Single plate double screen cavities

- Single piston double screen cavities

- Double piston four screen cavities b

- Double piston double screen cavities

contact us

- Batte Machinery Zhengzhou Co., Ltd.

- E-mail: info@battemachinery.com

- Skype: Battemachinery

- Tel: +86 371 67991755

- After-sales Tel: +86 371 67997677 / 67997877

- Mob: +86 15838331071

- Address: No.11 Changchun Road, High & New Technology Development Zone, Zhengzhou, China.

News

- Melt Pump Installation Schemes

- Loss in weight feeder application

- Structure of Batte spinning pumps

- Advantages of Batte gear spinning pu

- Effect of structural features of the

- Effect of material properties for in

- BATTE May is thriving!

- K 2016-The world’s No.1 Trade Fair

- Latest information about CHINAPLAS 2

Twin screw loss in weight metering feeder

Twin screw loss in weight metering feeder

Twin screw loss in weight metering feeder.pdf

Twin screw loss in weight metering feeder.pdf

Application of Twin screw metering feeder:

In the extrusion processing, it is common to add many material (such as color, flame retardant, glass fiber and so on) into extruder. In the process of continuous extrusion production, various material should be added to extruder continuously synchronized. And the adding speed of these materials should depend on corresponding formula, so metering feeder is necessary to control the adding speed. And one metering feeder control one material.

Loss-in-weigh feeders is suitable for plastic granules, powder, calcium carbonate, talcum powder, resin membrane powder, flour, starch and so on. Different material use different feeders.

Characteristics of Twin screw feeder:

◆ Generous and beautiful appearance: comparing with traditional feeders, Batte dose more improvements on feeders’ appearance.

◆ Small in size: easy to move, more suitable for changing and improving production process.

◆ Low noise: comparing with other feeders, noise of Batte feeders is up to perfect.

◆ Easy to clean and maintain: it’s easy to maintain in operation, meanwhile, very short maintenance time. Especially the control system, adopting the leading software and hardware, are nearly free-maintenance and long-service life.

◆ High feeding accuracy: Batte adds self-detection function when designing its feeders for more accuracy, it allows to detect attritions of parts and frequency variation timely, then revise them. So the feeder will not affect the feeding precision because a little change of the machine.

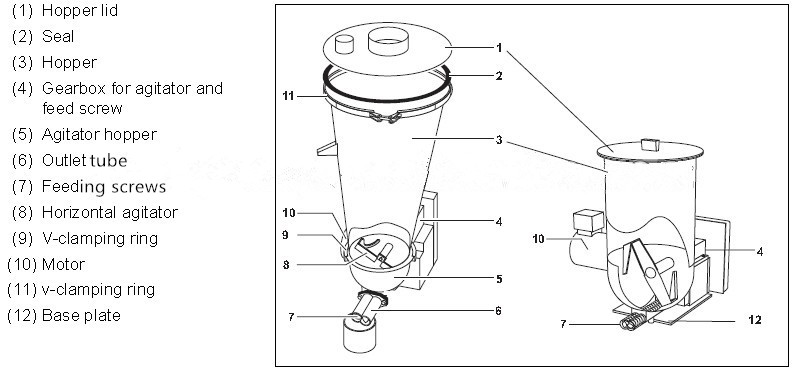

Structure of Twin screw loss in weight feeder:

Parameters of Twin screw loss in weight metering feeder:

| Type | Screw specification |

Capacity (L/H) |

Driving power (kw) |

Hopper (L) (optional) |

Feeding accuracy |

| BAT-MF-TS28 | 28 | 10-200 | 1.1 | 40-80 | ±0.2% |

| BAT-MF-TS38 | 38 | 30-400 | 1.1 | 40-100 | ±0.2% |

| BAT-MF-TS46 | 46 | 50-800 | 1.5 | 40-120 | ±0.2% |

| BAT-MF-TS64 | 64 | 60-1200 | 2.2 | 40-150 | ±0.2% |

Notes: The feeding capacity and accuracy will be affected by different materials.

Parameters of Twin screw loss in weight feeder:

| Type | Screw specification |

Capacity (L/H) |

Driving power (kw) |

Hopper (L) (optional) |

Feeding accuracy |

| BAT-TF-TS28 | 28 | 10-200 | 1.1 | 40-80 | ±0.5% |

| BAT-TF-TS38 | 38 | 30-400 | 1.1 | 40-100 | ±0.5% |

| BAT-TF-TS46 | 46 | 50-800 | 1.5 | 40-120 | ±0.5% |

| BAT-TF-TS64 | 64 | 60-1200 | 1.5 | 40-150 | ±0.5% |

Notes: The feeding capacity and accuracy will be affected by different materials.

Twin screw loss in weight metering feeder.pdf

Twin screw loss in weight metering feeder.pdf

Next:Single screw gravimetric dosing feeder