Melt Pump

- Gear melt pump for high viscosity me

- Plastic melt pump for extruder

- Extruding pump for polymer

- Pressurized melt pump for extruder

- High temperature and high pressure m

- Gear pump for rubber extruder

- Polymer melt pump for reaction kettl

- Melt pump for reaction kettle

- Spinning gear metering pump

- Chemical transporting and dosing pum

Feeding System

- Liquid loss in weight feeder

- Volume feeding machine

- Multi-component loss in weight feede

- Micro loss in weight metering feeder

- Single screw gravimetric dosing feed

- Twin screw loss in weight metering f

Screen Changer

- Manual control screen changer

- Double plate hydraulic screen change

- Automatic mesh belt continuous scree

- Double piston four screen cavities s

- Single plate double screen cavities

- Single piston double screen cavities

- Double piston four screen cavities b

- Double piston double screen cavities

contact us

- Batte Machinery Zhengzhou Co., Ltd.

- E-mail: info@battemachinery.com

- Skype: Battemachinery

- Tel: +86 371 67991755

- After-sales Tel: +86 371 67997677 / 67997877

- Mob: +86 15838331071

- Address: No.11 Changchun Road, High & New Technology Development Zone, Zhengzhou, China.

News

- Melt Pump Installation Schemes

- Loss in weight feeder application

- Structure of Batte spinning pumps

- Advantages of Batte gear spinning pu

- Effect of structural features of the

- Effect of material properties for in

- BATTE May is thriving!

- K 2016-The world’s No.1 Trade Fair

- Latest information about CHINAPLAS 2

Multi-component loss in weight feeder

Multi-component loss in weight feeder

Multi-component loss in weight feeder.pdf

Multi-component loss in weight feeder.pdf

Application of Multi-component loss in weight feeder:

This feeder belongs to static weighing metering, and it is suitable for intermittent feeding or single-pass feeding. It mainly used for the following material:

◆ Granules, diffluent powder.

◆ Regular and uniform granular material

◆ Strict with the material.

In other words, multi-component feeders is not suitable for powder and poor liquidity materials, because it has an bad affect on the environment when the material is powder.

Characteristics of Multi-component feeder:

◆ Wide range of application, suitable for plastic granules, power, calcium carbonate, talcum powder, resin membrane powder, flour, starch and so on.

◆ Convenient assembly and disassembly, easy to clean up.

◆ Technical strength, German original technical equipment, performance pre-sales guidance service.

◆ Stable discharging performance, high precision, wide range of output capacity.

◆ The static accuracy of loo-in-wight can reach 0.1%, repetitive dynamic accuracy can reach 0.3%.

◆ The control instrument of weight loss scale choose RWC-800CF, high precision, high anti-interference performance and more real-time.

◆ Sensor chooses Ronan high precision strain-gauge, aser seal welding has advantages of high precision and good reliability. Suitable for bad conditions.

◆ Flexible control system: this system can achieve manual & automatic control feeding, material makeup. Free changeover between manual mode and automatic mode.

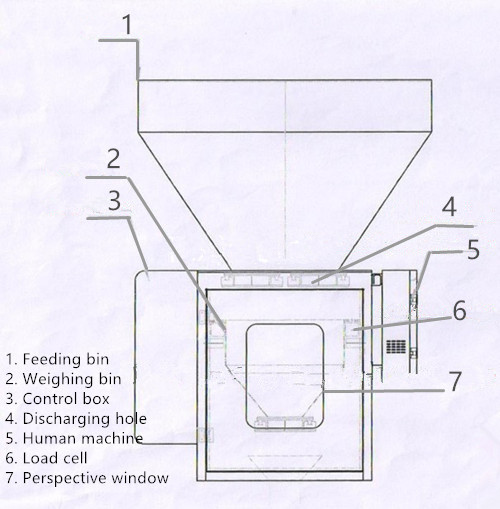

Structure of Multi-component gravimetric feeders:

Parameters of Multi-component feeder:

| Type | Feeding Rate | Feeding Accuracy (%) |

Blending Motor Powder |

Internal Resolution of Weighing Chip |

| BAT-LF-2 | 100-1000L/H | more or less 0.5% | 0.75 KW | 1/2 million |

| BAT-LF-3 | 150-1500L/H | more or less 0.5% | 0.75 KW | 1/2 million |

| BAT-LF-4 | 200-2000L/H | more or less 0.5% | 0.75 KW | 1/2 million |

| BAT-LF-5 | 250-2500L/H | more or less 0.5% | 0.75 KW | 1/2 million |

| BAT-LF-6 | 300-3000L/H | more or less 0.5% | 0.75 KW | 1/2 million |

| BAT-LF-7 | 350-3500L/H | more or less 0.5% | 0.75 KW | 1/2 million |

Notes: The feeding capacity and accuracy will be affected by different materials.

Multi-component loss in weight feeder.pdf

Multi-component loss in weight feeder.pdf

Next:Volume feeding machine